Crown Glass 2.0

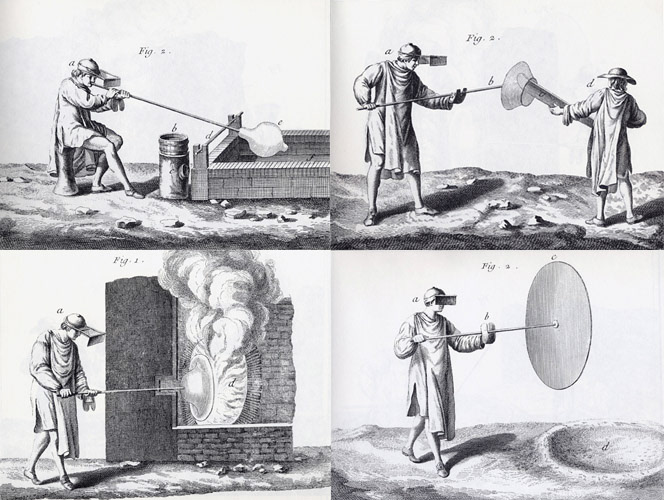

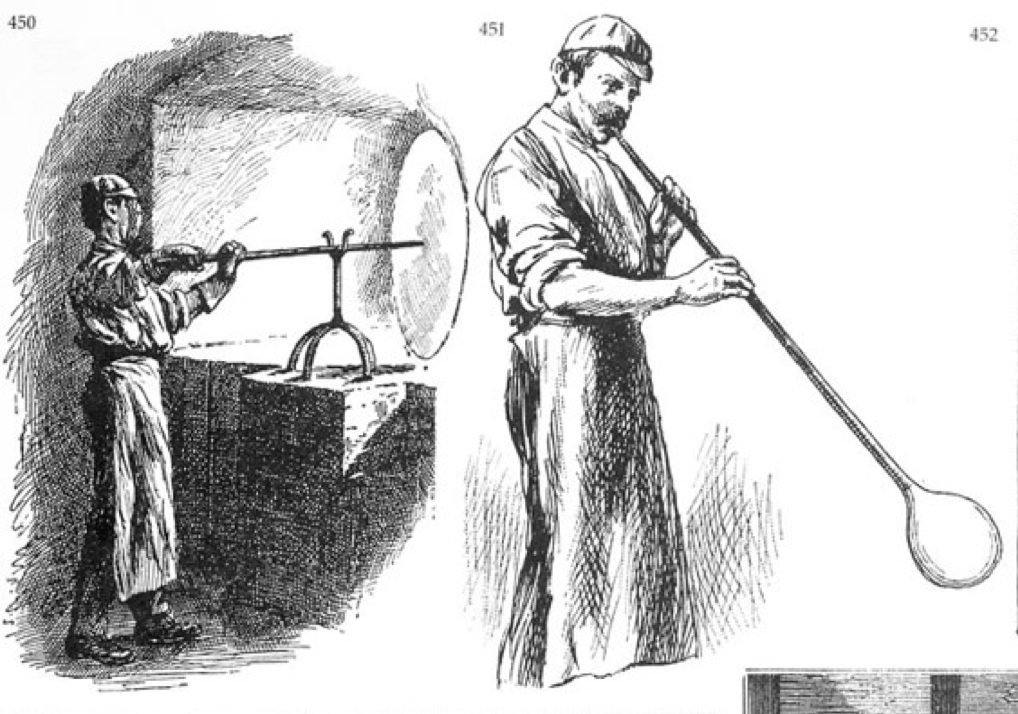

Early Georgian sash windows, limited by the manufacturing processes of the time, were made using crown glass-a wind-blown glass, that was later spun by hand, leaving a rippling effect on the glass surface. A trace remnant of its process of production. Thanks to industrialization, glass production became increasingly standardised and allowed for bigger glass panes. Although this provided larger windows, without the interruptions of small frames holding each piece together, it also erased any trace from its manufacturing process as well as any texture or imperfections the prior crown glass had.

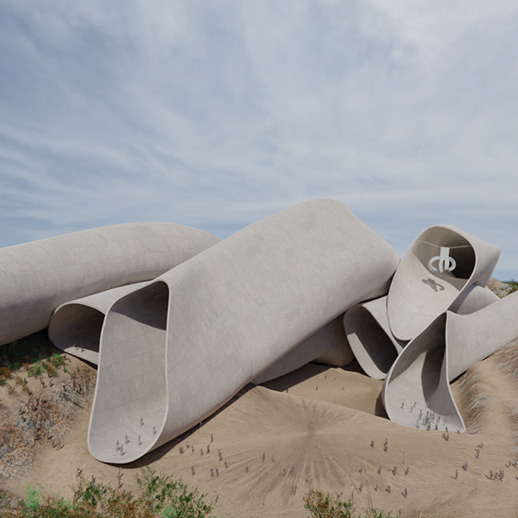

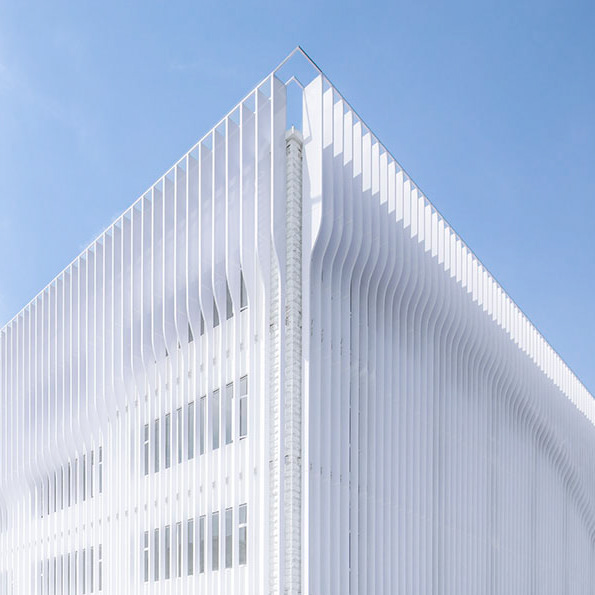

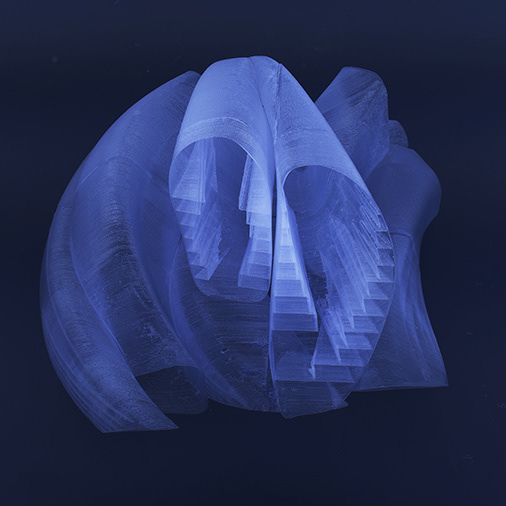

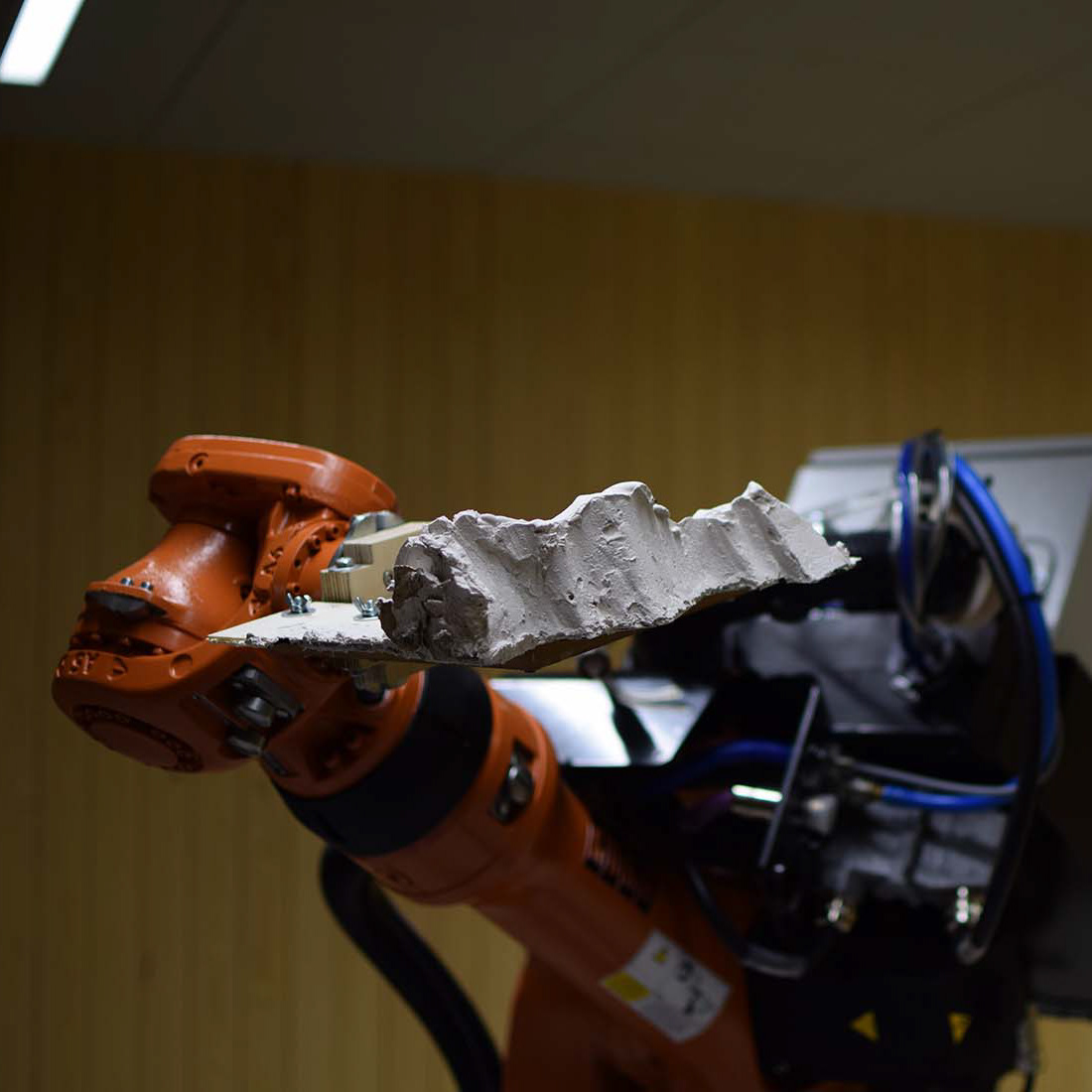

This proposal sees the role of the window, not only as a viewing or ventilation device, but as an experimental subject in manufacturing processes of different materials, mainly glass. Through the use of 3d printed glass, it intensifies the ripple effect that added texture to the early crown glass without the need of smaller frames, bringing back the exquisite on this material, previously erased by industrialization.

This exercise was performed as part of Chadha Ranch’s and Non-Office’s United Front: An Exquisite Corpse Façade Charrette, on view at the 2024 Available Works Art Book Fair, where nine participants were asked to re-create a component from a generic Georgian Townhouse.

Participants:

1)Entrance: Tom Hancocks 2)Entrance Condition: Jennifer Durand & Sergio Mutis 3)Ground Windows: Jerome Byron 4)First Floor Windows: A+A+A 5)Second Floor Windows: Juan Cantu 6)Cornice/Entablature: Guillermo Trapiello 7)Roofline/Pediment: Hannah Kim 8)Facade Material/Texture: John Clayson 9)Decorative Elements/Accents: Manifold